Push to connect fittings, as the name implies, it requires the simple connection of the fitting and tube & pipe, one end of water tube inserts into quick connector or stem connector inserts into tube, and then gently pushing it into place until the fit is snug and leak-proof. All quick connect tubing fittings from us can be installed without using any type of tools.

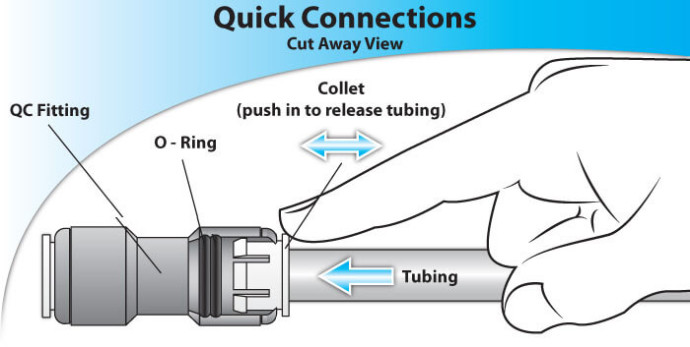

Quick connect fittings can be manufactured from polyformaldehyde (POM), PVC, copper or stainless steel. To meet the food grade requirement of water purifier tube fittings, Our quick connect fittings almost use food rank POM as raw material. it can be removed, rebuilt and reused, making it more cost-effective then traditional plumping connections. The typical quick connect fitting relies on a reusable O-ring to seal and a collect to grip the pipe. Installation is commonly as easy as cutting the pipe to length, cleaning the pipe end and then sliding the quick connect fitting onto the pipe.

A push fit is typically good option for household reverse osmosis water purifiers, to connect small dimension water tube. Regarding the complex pipelines in water purifiers, we have developed variety of quick fittings, divided them by type: straight, elbow, tee and Y type, divided them by dimension: union/equal quick connector, male/female threaded quick fitting, stem fitting, check valve and plastic hand ball valve.

With many people looking for new ways to be green and environmentally friendly in all walks of life, the quick connection fitting is gaining in popularity among plumping choices in light manufacturing, as well as new build construction and remodeling alike. Especially, in water purifier systems, which is gradually spreading to every household. The absence of glues, solder and chemicals and any special tools to install the pipes connection of the water purifiers are time-saving and cost-friendly to many budgets, which highly improve the production efficiency.

The quick connect fitting is not limited to basic plumbing systems. Many manufacturers are producing quick connect systems intended for high-pressure compressed air systems as well as gas and propane supply lines. The same reliable and reusable connectors are used with these systems, making changes in the routing or the addition of future lines as easy as plugging the new connections in. It is common, however, for all of the differing systems to use dedicated color coding in the pipe and connectors. This makes it easy to identify the proper line when the time comes to add on to the system.